Once you’ve decided where to point the sensors, how do you accurately attach them?

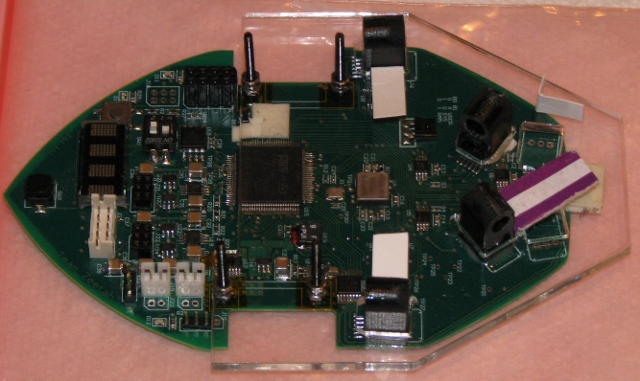

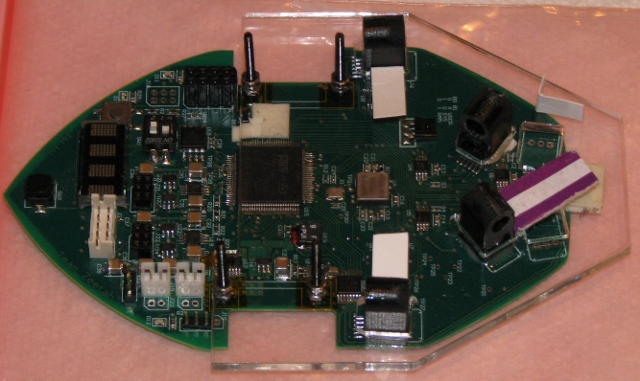

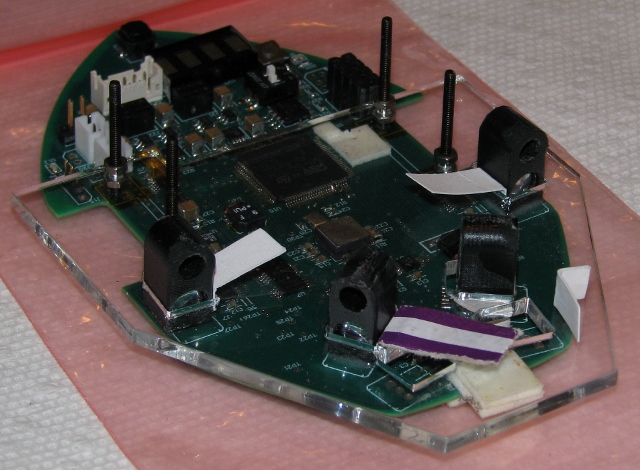

Since I use plastic blocks for my sensors, I used a laser cutter and cut out an alignment jig using an acrylic sheet (see pictures below). The jig is attached to the mouse using the drive unit’s mounting holes.

The holes in the jig for the sensor blocks are slightly oversized compared to the sensor blocks and I use a paper shim to hold the sensor block in the jig when I’m waiting for the glue to dry. When the glue dries, I remove the paper shim so that I’m not applying any unnecessary force on the blocks and I’m easily able to remove the jig.

Another benefit of the oversized holes is that if I have to reattach one block, I can do so without worrying about stressing the other blocks.

If I was to redo the mouse PCB, I’d add tooling holes so that I can attach the alignment jig without removing the drive unit.

Please do share how you go about doing this.

Brilliant!

This is really a simple and great idea.