The problem I now face is the same one that Peter ran into between Decimus 1 and 2 of how to share the code base. When I started ZV, I started from the ZIV code base and that forced me to abstract out some of the low level code. I’m hopeful that I can continue that trend. We’ll see. I write more about it as I make progress.

The next issue was design targets. Based on ZV, we decided that we would like ZVI to have a similar rotational inertia but weigh under 85g. The current estimate is 83g. Once we build the HW, we will know how close we got to the 83g number and the forward and rotational time constants.

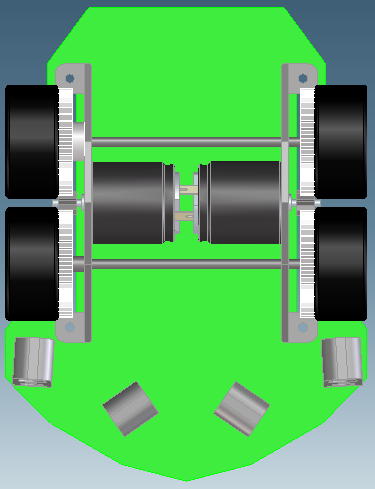

The gear ratio was really tricky. We’ve read that four wheel mice are achieving around 1.4g of acceleration with top speeds of 4+m/s. When I adjust the gear ratio to hit 4m/s, the forward and rotational time constants are very high and when I fix the time constants, the top speed is less than 3m/s. In the end, I decided to go with the lower time constants and gave up on the top speed. If we can indeed control the mouse, then we’ll over rev. the motor to get the top speed. The other issue with top speed was that I wanted to stay with a 0.5 module gear profile. The lower ratio meant that we couldn’t use axles because the axles would interfere with the motors. Fortunately, Pierre is comfortable using half-shafts instead of an axle and so we went with this approach. It eventually turned out that the gear ratio we settled on 8:42 allows us to use axles so if we run into problems with half-shafts, we’ll try the axle approach. The other reason for not using axles is that they push the batteries further out which increases the rotational inertia.

Another challenge was picking the tires. The choices were the ones used for Mini-Z cars. However, there appear to be two different diameters – 17mm and 19mm. If we use a small diameter rim, then the gear hits the ground. If we use a large diameter rim, then the tires hit each other because of the gear ratio constraint. In the end, I implemented the constraints as equations in Excel and tried a few different combinations to optimize the top speed, the reflected inertias while making sure there was a gap between the tires.

One item that simplifies four wheel mouse design is that there is only one motor choice the 1717 motor from Faulhaber. I looked at motors in servos and other sources but couldn’t find a comparable/better motor.

I did look at different wheel widths but settled on 74mm just like ZV. The length was a harder decision. The longer you make the mouse, the less the weight transfer to the skid pad when accelerating/decelerating but this also means higher rotational inertia. In the end, I decided to use the front set of wheels as the “center” of the mouse and made the front of the mouse 48mm long and the rear 44.6mm long. Now that I think more about this, I should have made the rear slightly longer and the front shorter because when braking, the friction helps you slow down more.

The other challenge when doing the mechanical design was getting the gearing right. I had used Dynamic CAD to design ZV but I found it hard to use. Based on a co-worker’s suggestion, I took a look at Creo Elements Direct Modeling Personal Edition from PTC and after a few sessions with my co-worker have been able to use it quite effectively. The program is free and allows you to create designs that have up to 60 parts. For some reason, I get how to use the program and can say that I’ve finally found a mechanical CAD program I like. One of the nice things about it is that you can import models from different sources and so I was able to pull in the motor models and use them directly. Generating mechanical drawings is quite “easy”. I think I am barely scratching the capabilities but I’m able to get by.

How would you connect gearwheel with rim and bearing? Would it be self made or MiniZ rim? Thanks for answer 🙂

We are experimenting with making the rim and gear out of one piece of plastic.

If you have access to the Mini-Z parts, I think another approach is the one you point out – use a MiniZ rim with gear. I’ve seen several mice in Japan do this. I think this will yield light weight components.